Why is it called a Universal Electric Motor?

The universal electric motor is so named because it is the only motor that can be connected to both AC and DC power.

- When the universal motor is connected to a DC power source with a constant load, the speed and power increase in proportion to the applied voltage.

- When this motor is connected to an AC power source at a constant load, the speed and power increase in proportion to the applied voltage, starting at 3000 rpm.

In the universal motor, the speed for a given voltage in AC is lower than the speed that would be obtained if the same voltage were applied in DC.

Small universal motors typically deliver 0.01 to 0.035 hp and speeds up to 3000 rpm. Other universal motors deliver 0.05 to 2.0 hp at 5000 rpm or higher.

The principle of operation of this electric motor is determined by the motor effect produced by a conductor through which an electric current flows and which is subjected to a magnetic field.

The magnetomotive effect causes displacement and therefore rotation.

Universal Motor Construction

- Conductive coils: These are known as inductors or inductive fields.

- Inductive Coil: This is the wound rotor and is known by the name of armature.

- Brushes: They are made of carbon because it is a soft material and has a negative temperature coefficient.

- Springs: They are used to hold the brushes in place by mechanical pressure.

- Covers or shields: They are used to support the motor shaft and give mechanical structure to the motor.

Universal Electric Motor

Universal Motor Features

- Works with AC and DC

- Has a very high starting torque

- Speed directly proportional to current

- Used in hand tools, home appliances

- To reverse the direction of rotation, reverse the direction of the current in any of the windings.

Universal Electric Motor Operating Principle

The operation of the universal electric motor is based on Laplace’s law. The inductor winding and the induced winding are connected in series.

Since the two windings have the same current flow, the inductor winding forms the magnetic field. The winding induced by Laplace’s law, traversed by the current and subjected to the influence of the inducing magnetic field, moves, resulting in the rotation of the rotor. As you increase the field, the force increases and so does the speed.

The magnetic field generated by the inductive coil causes a deformation of the inductor flux called the armature reaction.

In alternating current (AC) or direct current (DC), the sense is maintained by the instantaneous action of each particular alternation.

In AC, a CEMF (counter-electromotive force) by the transformer effect and by the generator effect. In DC, only the generator effect.

Speed control on the universal motor

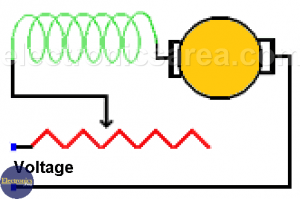

1. By rheostat: Varying the rheostat arrow varies the current in the motor.

Universal electric motor – Rheostat speed control

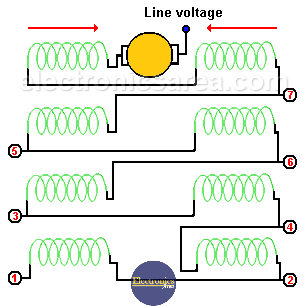

2. By switching resistors: By changing the connection (switching) between the numbered terminals, you change the resistance and therefore the amount of current delivered to the motor. The higher the resistance, the lower the current.

Universal Electric Motor – Speed Control Resistors

More Electric Motor Tutorials: